Array incidence loss (IAM)

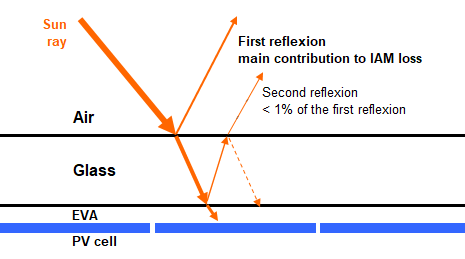

The incidence effect (the designated term is IAM for Incidence Angle Modifier) corresponds to the decrease of the irradiance really reaching the PV cells' surface, with respect to irradiance under normal incidence. This decrease is mainly due to reflections on the glass cover, which increases with the incidence angle.

The transmission loss is a general phenomenon, due to the reflection and transmission of the sun's rays at each material interface (air-glass, glass-EVA, EVA-cell), as well as some absorption in the glass. This arises for any incident ray. For normal incidence, the reflection is of the order of 5%, and is included in the measured STC performance. The IAM only concerns the angular dependency of this effect, i.e. it is normalized to the transmission at perpendicular incidence (0° incidence angle).

PVsyst uses an IAM function, which describes the deficit of transmission as a function of the incidence angle. This function is applied to the beam, diffuse, and albedo components, using an integral over all "seen" directions, supposing an isotropic distribution of the diffuse irradiance.

Physics Models

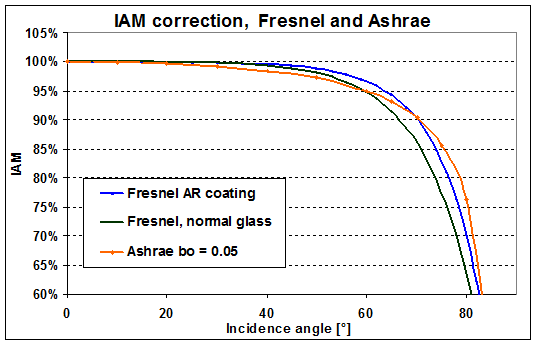

Several models predict the light effectively reaching the cell's surface as a function of the incidence angle. Since PVsyst 6.67, Fresnel's laws are used. In older PVsyst versions, the ASHRAE parametrization was used.

Fresnel's laws

This model is based on the physical behaviour of light: the Fresnel's Laws describe light transmission and reflection at the interface of two transparent materials of different refraction indexes n1 and n2. This is a very general behaviour, derived from Maxwell's equations describing electromagnetism.

Fresnel's laws are first applied to the air-glass interface; they describe the reflected ray and the transmitted ray. At the next interface (glass-EVA), the Fresnel equations are applied again to the transmitted ray. Light trapping or multiple reflections are not modelled in PVsyst.

The exact IAM profile depends on the different material layers present in the module. PVsyst considers:

- Anti-reflective (AR) coating, if present

- Glass

- EVA

Reflections from the cell's silicon, busbars or fingers are neglected in the IAM model. The figure below shows the IAM profile for normal glass and AR-coated glass and compares it to the ASHRAE parametrization. It shows that the ASHRAE parametrization underestimates the IAM value at medium angles (30 to 60°) and overestimates them over these values.

ASHRAE Parametrization (deprecated)

In the past, the IAM function has often been estimated using the "ASHRAE" parametrization (proposed in the 1980s by this American standards organization), depending on only one parameter bo:

$FIAM = 1 - bo · (1/cos i - 1)$ where i = incidence angle on the plane.

For single-glazed thermal solar modules, the usually accepted value for bo is of the order of 0.1. But in a PV module, the lower interface, in contact with the cell, presents a high refraction index, and our specific measurements on real crystalline modules actually indicate a value of bo = 0.05.

Sandia model (deprecated)

The Sandia IAM model has been used in the past for modules belonging to the Sandia database (not supported anymore). It is based on a 5th-order polynomial interpolation (hence relying on 6 coefficients from b0 to b5).

The model should not be used for modules outside the database, although the option is available in PVsyst. In case one selects the Sandia model nonetheless, the following default parameters are used:

$b0 = 1, b1 = -2.438E-3, b2 = 3.103E-4 , b3= -1.246E-5 , b4 = 2.11E-7, b5 = -1.36E-9$

Implementation in PVsyst

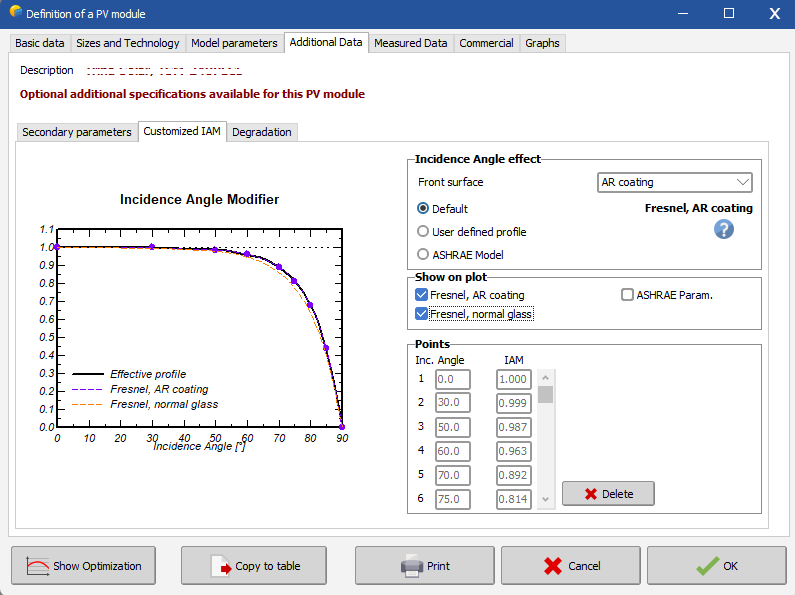

Definition in the PV module

Each module is associated with an IAM model or measurement. When opening a PV panel file (.PAN file), the IAM is defined in "Additional data > Customized IAM".

- When default is selected, Fresnel's equations are used and the front surface material should be defined from the list on the right. The refractive indexes in Fresnel equations will be set accordingly. The options are:

- Normal glass

- AR coating (glass + anti-reflective coating)

- Textured glass (currently identical to AR coating)

- Plastic (currently identical to normal glass)

- Not defined (legacy modules, applies the deprecated ASHRAE parametrization)

- The IAM can be defined from measurements by selecting User defined profile. We recommend great care when using a user-defined profile, as some manufacturers are known to overestimate the IAM performance.

- ASHRAE model (not recommended, available for backwards compatibility)

Note that:

- For modules in our database, if a manufacturer wants to set their own IAM profile, PVsyst requires a detailed measurement report established by an independent laboratory and performed indoors.

- For bifacial systems, the IAM losses on the rear side of the PV modules are always calculated using the simple Fresnel model for glass without anti-reflective coating.

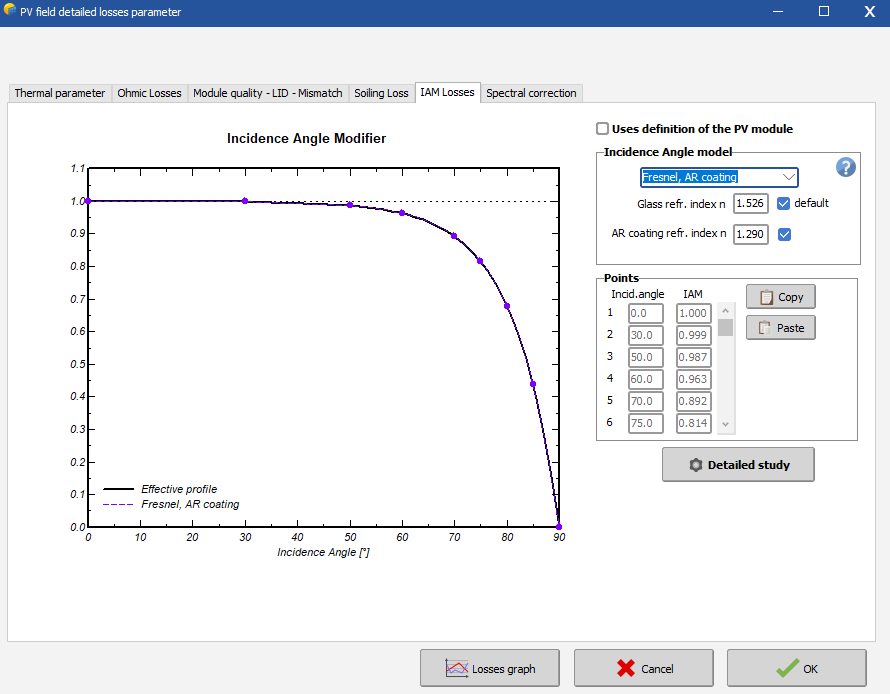

Use in the simulation

IAM losses are calculated by default from the PV module definition. However, the IAM model can be selected or compared from the Detailed Losses window, in the IAM losses tab. The IAM definition from the PV modules can be overwritten by unselecting the checkbox "Uses definition of the PV module". Available options are:

- Fresnel model (recommended with default coefficients).

- User defined: IAM measurements can be entered manually. To be used with caution.

- ASHRAE (deprecated)

- Sandia (deprecated)

Comparing models

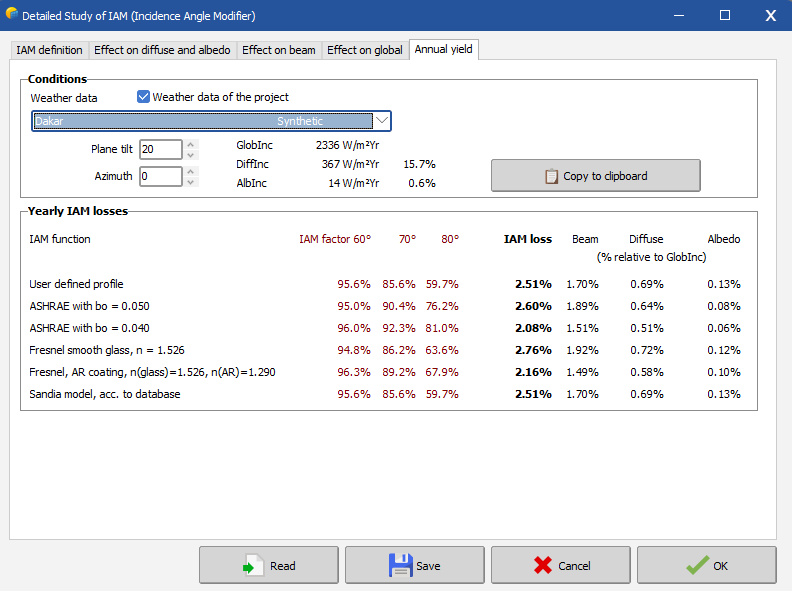

The Detailed Losses dialog has a button Detailed Study, which provides a complete analysis and helps understand the IAM effects as a function of the irradiance angular distributions (beam, diffuse and albedo).

The differences between IAM models and their impact on the full-year simulation may be studied in detail (shown below). We recommend using this tool before using a user-defined profile for the IAM. The energy yield should not vary significantly when compared to the Fresnel model.

Note that differences in energy yield due to the choice of IAM model also depend on the weather data, the plane orientation, etc. As an example, a simulation in Geneva gave:

- Fresnel Normal glass slightly lower than the ASHRAE (-0.25%)

- Difference Fresnel AR coating and normal glass 0.75%.

Moreover, differences in yearly energy yield computed from unrealistic user-defined IAM profiles and the default Fresnel model with AR coating can reach 2%.

IAM Measurements

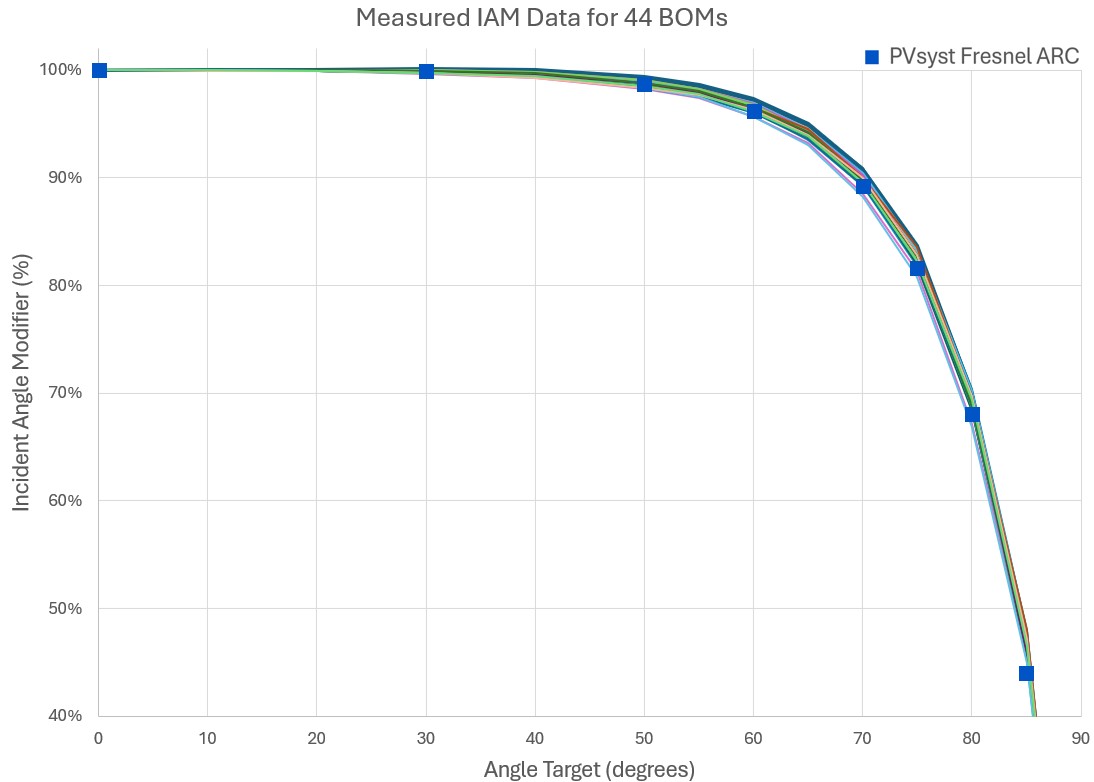

The global trend in IAM measurements seems to be in good agreement with the Fresnel model used in PVsyst. In their 2024 IAM test results (https://scorecard.pvel.com/iam/), PVEL measured 44 modules and compared them to the modelling from Fresnel's laws for glass with AR coating, as shown in the figure below.

AR coating lifetime

The lifetime of AR coatings and their deterioration over time is not well measured. The 2023 ITRPV roadmap estimates it at 15 years in 2023 and increasing to 25 years in 2031. PVsyst does not model any changes in IAM due to potential degradation of AR coatings.